As I become a card-carrying claybotter, I am teaching myself new software: Fusion 360 and Potterware for modeling, and SImplify3D for slicing. As I start to print my work, I have encountered a puzzle. If anyone can help solve, I’d be so grateful. I’m told that it just comes with trial and error and experience. This may be true. Then again, any outside help is welcome!

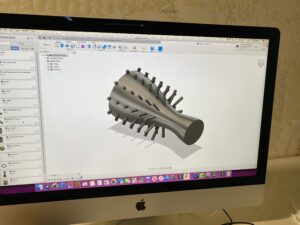

This is a model in Fusion 360:

Notice how it is rendered as a stiff shape. If I were printing to a typical 3D plastic printer, the bottle with spikes would be pretty true to this rendering.

This is how it printed in clay on the Scara 3D Potterbot:

Notice how it has loops and droops to portray the spikes. I got great feedback from this experiment. I can see how much the spikes in my model can protrude before the “loop” becomes untenable. I can understand a little about spacing and ratio to nozzle and extrusion sizes.

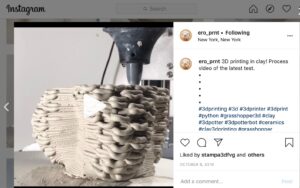

However, when I look at images I love on Instagram, I have no idea how to achieve them. Here a few that I aspire to understand:

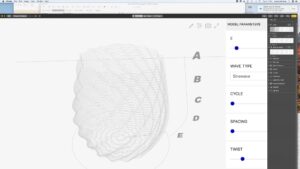

I know that some of these examples I like were created on software called Potterware from Emerging Objects. I have also printed a couple of Potterware objects – here is one:

Unfortunately, the models in Potterware only appear in wireframe, there is no renderer at all.

And because they get printed directly by the 3D Potterbot Scara, they don’t get sliced in slicing software, which would give me more feedback about the shape, I am in the dark too.

So welcome to this strange world of mental extrapolation. I think Potterware doesn’t have a renderer because it’s cloud software and they are trying to economize on bandwidth. If it weren’t such a big deal to 3D print an actual clay pot, I wouldn’t mind. But, as I’ll show in future blog posts, committing to a clay print takes some work, and I wish I knew better what I was doing.

More soon! —Your faithful Claybottress…

6 comments

This is fascinating!

And frustrating to me! But yes, a brain twister–or, em…fascinating.

Sounds challenging!

This is an exciting journey and I will be there shoulder to shoulder trying to figure it all out. This tool has fostered a profound shift in how I think about clay as an artistic medium.

I can’t wait to collaborate with you. I admire your knowledge and artistry so much, and what a great privilege it will be to see you create with this new tool. I am thinking, now with 8 tubes filled, it’s time to print bigger than ever before. Waiting game for CV to finish its way with us, and get back to making stuff!

I feel like the shape of the protrusions changes the loop. Instead of rods, maybe discs? Make the height of the disc the same as the nozzle diameter?

Comments are closed.